Gears have been pivotal components in machinery since ancient times, driving innovation and enabling complex mechanical operations.

Gears have been pivotal components in machinery since ancient times, driving innovation and enabling complex mechanical operations.

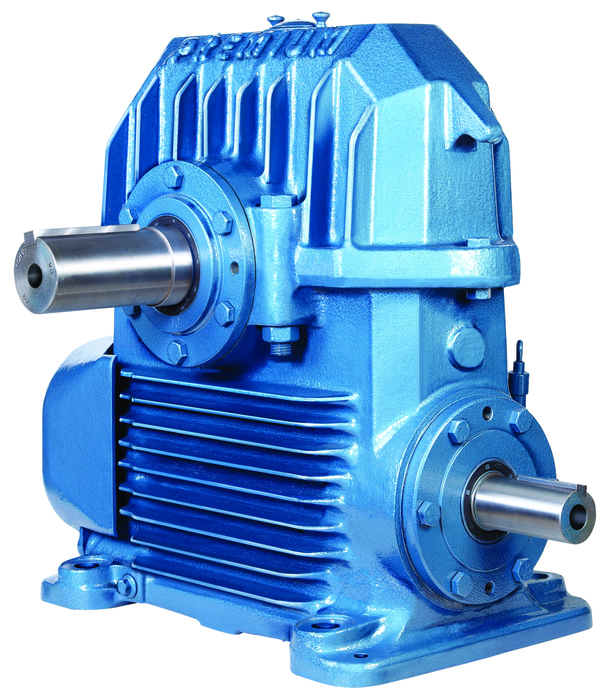

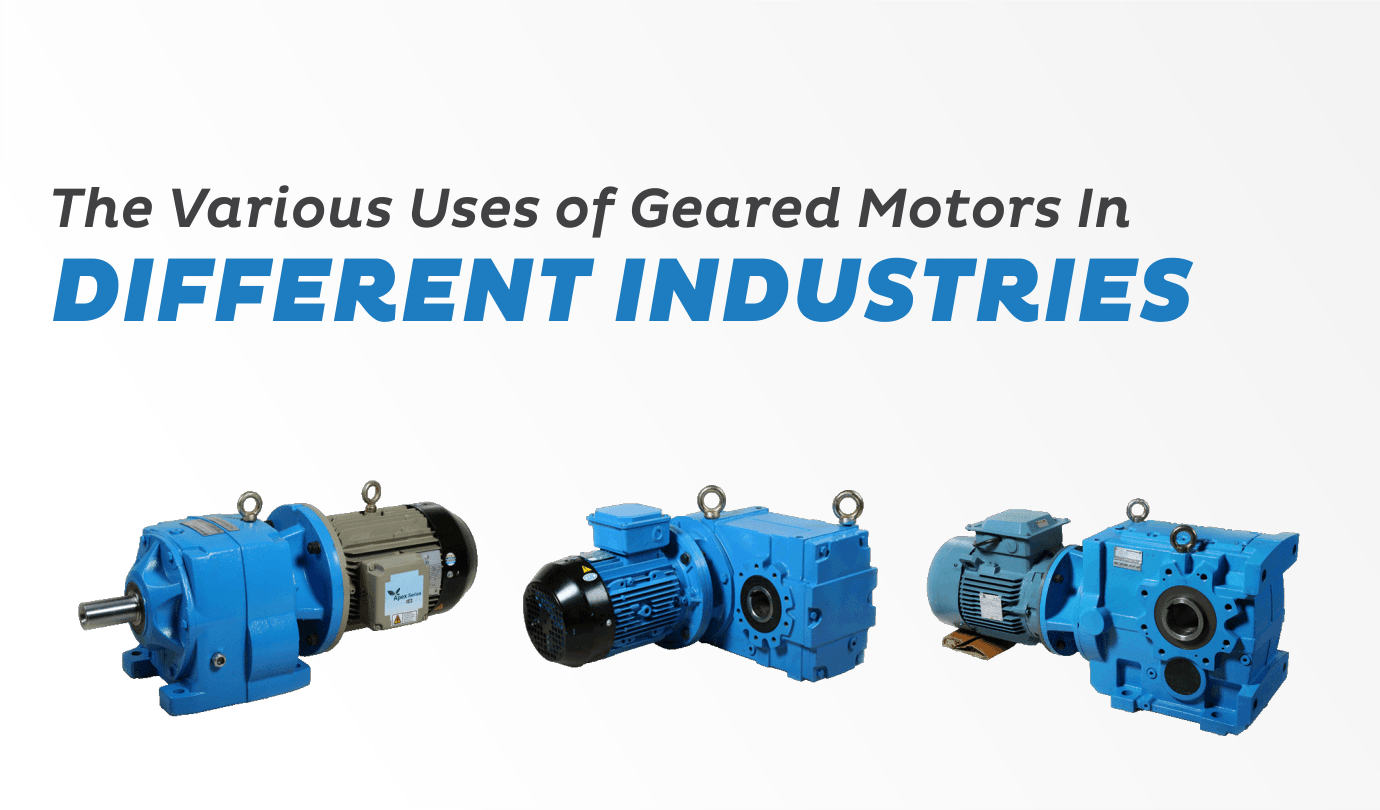

A geared motor, as the name suggests is an all-in-one combination of a gearbox and an electric motor.

Choosing the proper coupling for the job at hand requires asking the appropriate questions before defining a certain form.

Geared vs. gearless traction elevator is a common question that builders are faced with on all projects. The answer is unclear.

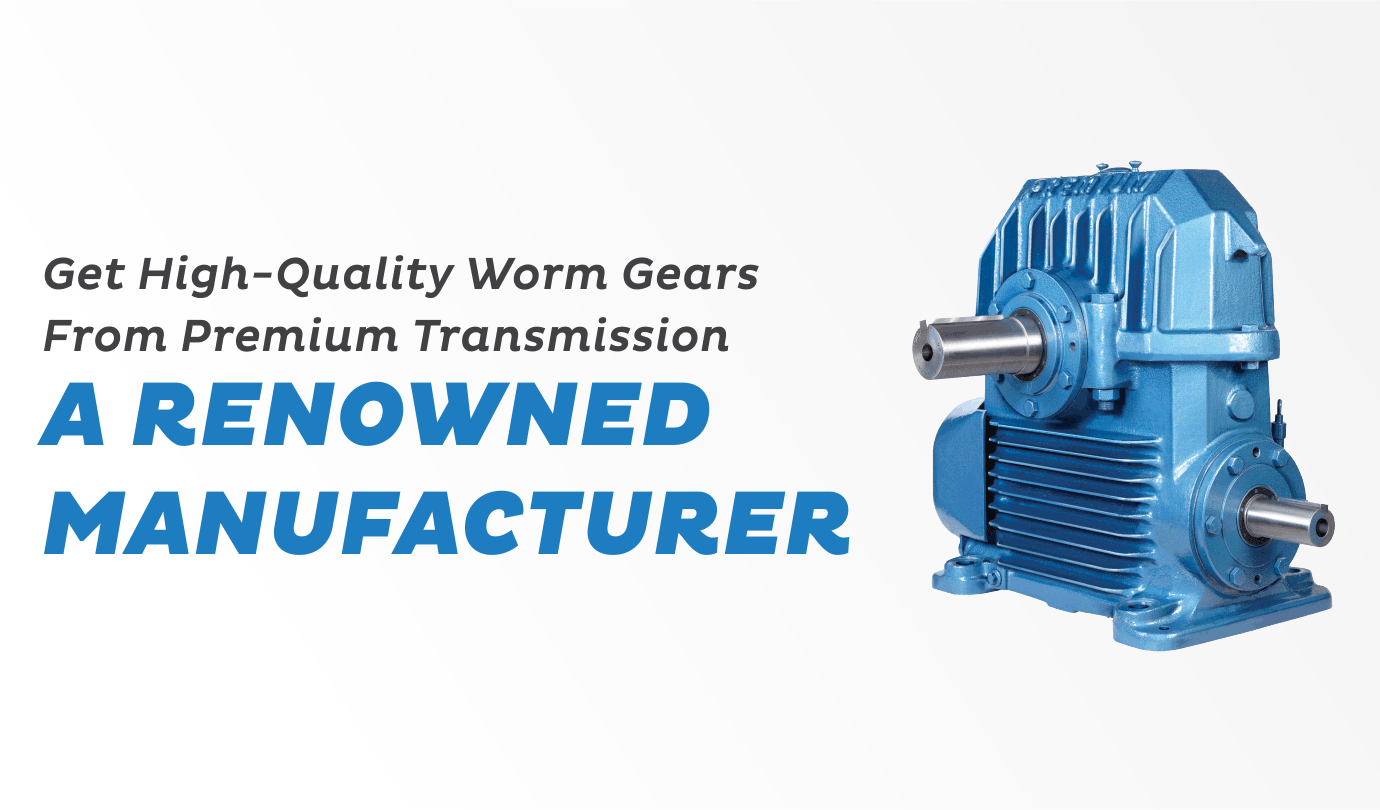

Speaking of Industries, worm gears and helical gears are the two main types of gears that are widely used in several Industrial applications

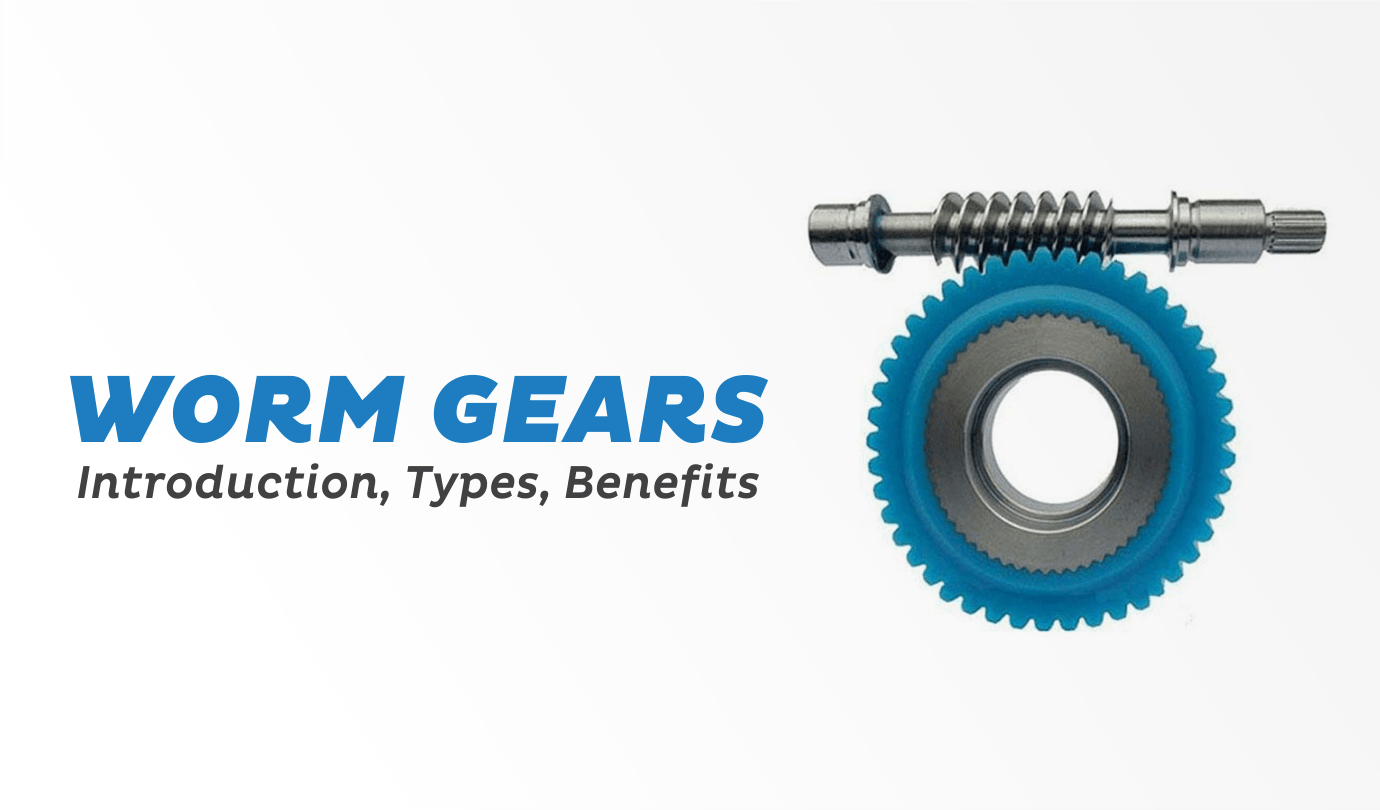

Worm gears are used in a variety of applications, including industrial, heavy equipment, and even consumer products.

Worm gears are made up of a worm and a gear (also known as a worm wheel), with non-parallel, non-intersecting shafts that are positioned 90 degrees to each other.

The field of mechanical engineering is rich with components designed to solve complex problems of motion and force.

Reduce the rotational speed of one shaft while increasing the torque transmitted to another using a helical gear.

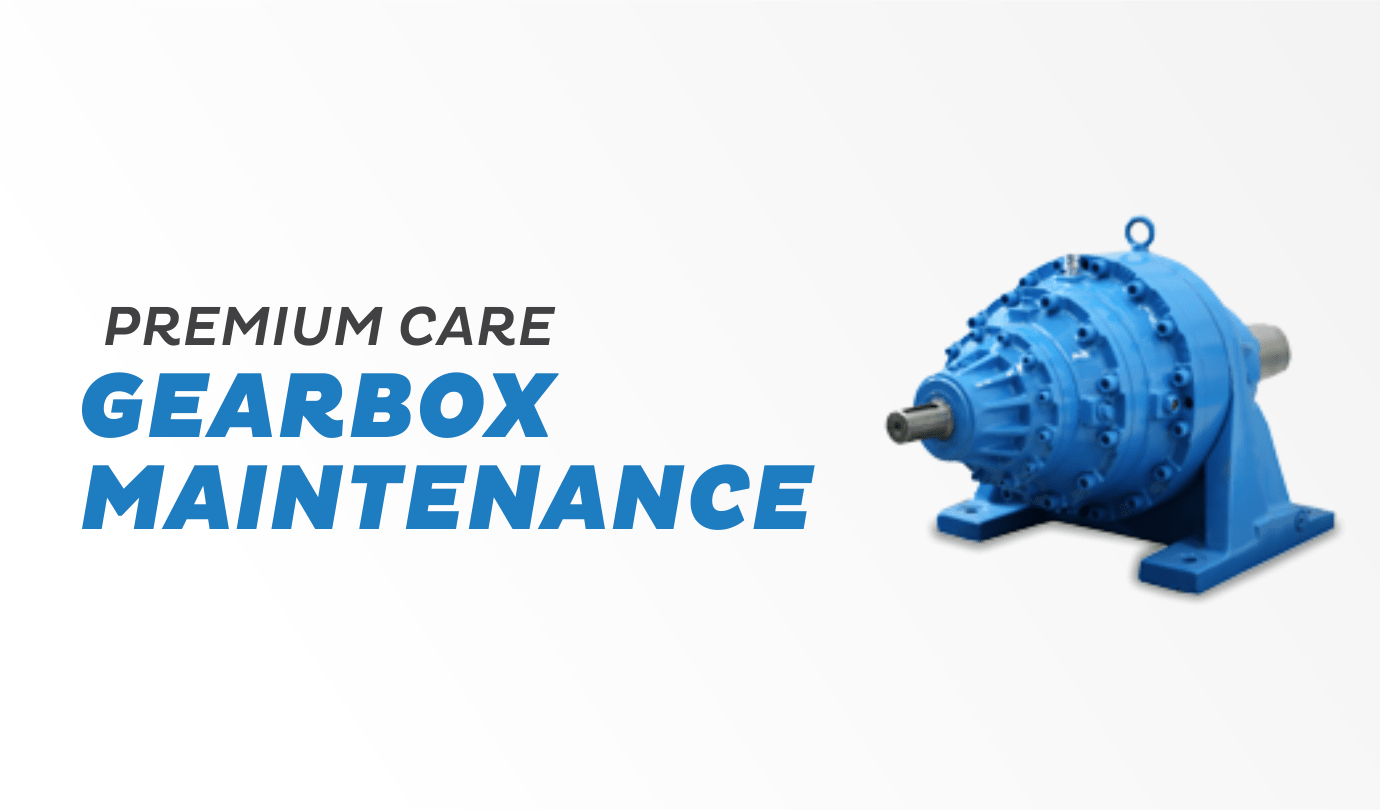

The gearbox is the engine of any machine or equipment; its failure is undesirable and may result in significant financial losses for the business.

The sugar business extensively uses a wide range of equipment throughout sugar manufacturing, from sugar cane and beet harvesters to feed conveyors.

The servo motor uses the flange planetary gearbox, a small gearbox with an output flange design, to reduce speed while still transferring large torques.

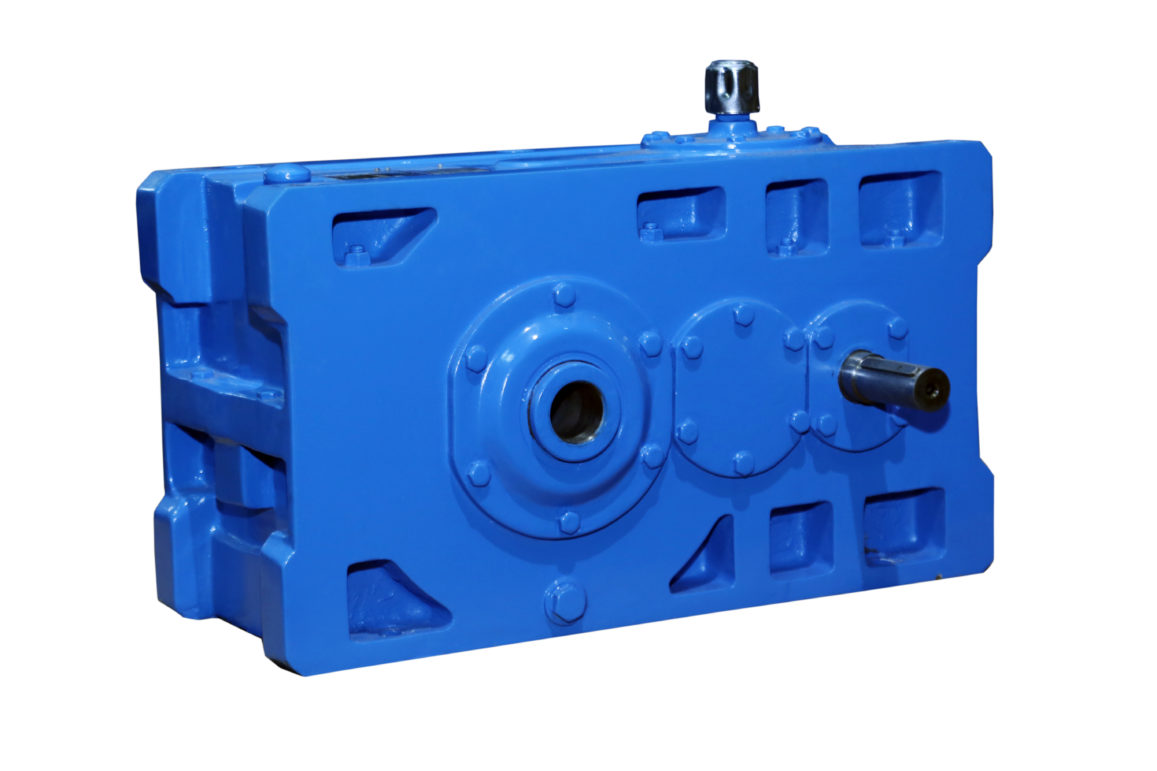

The gearbox is an integral part of machines used in a variety of industries and areas. The aim of gearboxes is to enhance the output torque or alter the motor’s speed (RPM).

A wheel-shaped gear with teeth is driven by a worm gear, which consists of a spirally threaded shaft called a worm but is basically a screw.

There are a variety of gearbox specifications for each machine or motor that may increase torque output via gear reduction.

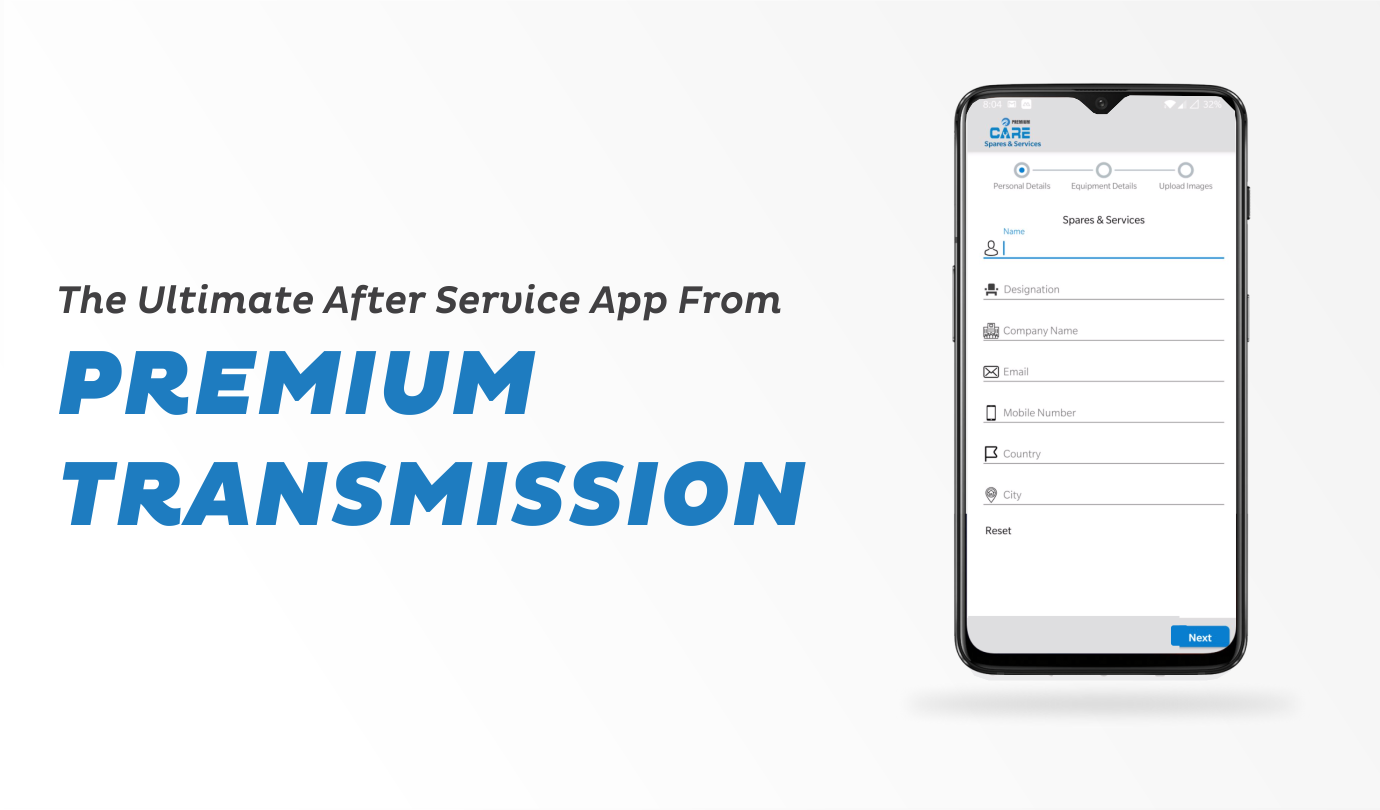

The three most important aspects of today’s manufacturing industry are warranty, maintenance and customer service.

Gears and their mechanical properties are widely used in a number of sectors to transmit motion and power in mechanical devices such as clocks,

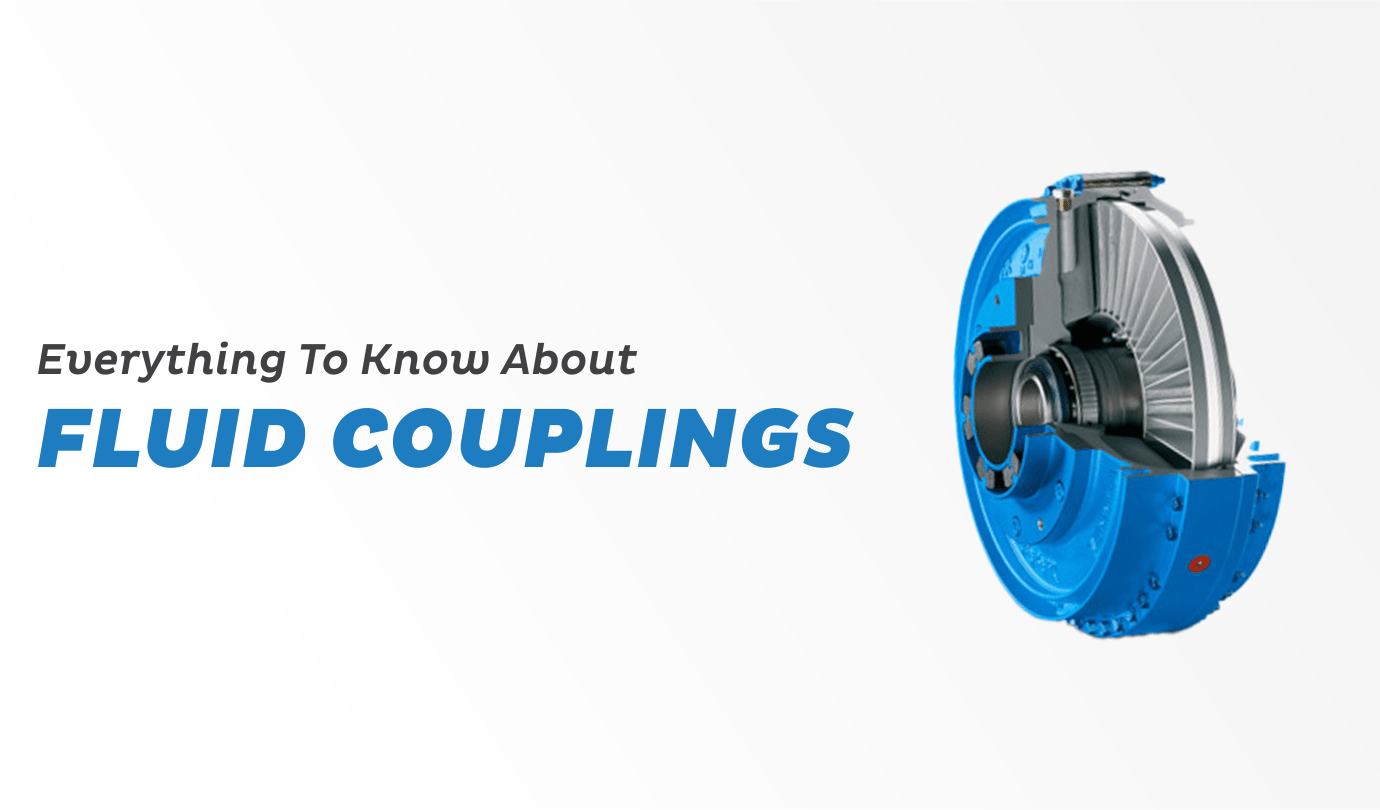

Hydraulic coupling is another term for fluid coupling. It is a hydrodynamic instrument that utilizes transmission fluid to transmit rotational motion from one shaft to another.

Whether you’re using worm gears, helical gears, or just about any sort of industrial gears, they are a critical component of many industrial motors and equipment, boosting torque production and modifying the direction of rotation.

In an industrial gearbox, the transmission of mechanical energy takes place inside the confines of an enclosure.

A gear reducer is an automated device that links a motor to a driven load. It is also referred to as a gearbox.

Industrial gearboxes are robust equipment that can resist high temperatures, pressures, and abrasive environments.

Gearboxes play a significant part in managing many industrial and repairing capabilities in today’s industrial environment.

If you require gears for a project or a product, it’s natural to be perplexed. However, it’s critical to pick the proper gear manufacturer that can match your needs.

If you require gears for a project or a product, it’s natural to be perplexed. However, it’s critical to pick the proper gear manufacturer that can match your needs.

Geared motors are the future of mechanical development. They are made up of a gearbox that is directly attached to the motor.

Gearmotors are electric motors that use a sort of gear system on the motor’s output. This gearing configuration is known as a gear reducer or gearbox.

It is necessary to go into greater detail when choosing the best gear motor for an application than simply selecting the best fitting output speed and torque.

The two most popular types of gear motors for industrial use are planetary gear motors and spur gear motors.

Among the gearbox manufacturers globally , Premium Transmission is a leading reputed brand.

A worm gear consists of a shaft and a spiral thread, and is used to engage and drive a toothed wheel.

Couplings are mechanical elements that incorporate two drive controls that allow a motion to be transferred from one part to the other.

Associated with different kinds of gears, worm gears are different and have unique features and applications.

The main objective for any business is to make money. As long as you have a product that customers desire, you’re in business.

The gearbox industry has been able to provide more and more innovative technology and services of lately, facilitating minimal downtime and optimum performance of gearboxes.

No matter how ever-present gearboxes have been, we generally tend to overlook their repair needs. A delayed routine maintenance will only lead to a setback on the entire production system.

A geared motor is a component whose mechanism adjusts the speed of the motor, leading them to operate at a certain speed.

Industrial Gearboxes are used in a various small scale and large-scale Industries and find a wide range of applications.